Introduction

In India, dental devices—from implants to orthodontic

brackets—must meet strict regulatory standards before entering the market. A Device

Master File (DMF) is one of the most critical documents in the Central Drugs

Standard Control Organization (CDSCO) registration process.

The DMF serves as a comprehensive dossier that demonstrates the

safety, quality, and performance of a dental device. For manufacturers and

importers, a well-prepared DMF is the key to smooth regulatory approval and

long-term compliance.

Regulatory Context

The CDSCO, under the Ministry of Health and Family Welfare (MoHFW),

regulates medical devices in India through the Medical Device Rules (MDR), 2017.

- Dental

devices are regulated as per their risk classification under these rules.

- Importers

and domestic manufacturers must submit a DMF during product registration

on the SUGAM portal.

CDSCO Expectations for DMF

A compliant DMF for dental devices should follow the structure

outlined in MDR, 2017 and align with ISO 13485 quality requirements.

Key Sections of a DMF:

- Administrative

Information – Manufacturer/importer details, contact information,

manufacturing site address, and license/registration numbers.

- Device

Description – Technical specifications, model variations, and accessories.

- Intended

Use – Clinical purpose, target patient group, and environment of use.

- Manufacturing

Process – Overview of manufacturing steps, in-process controls, and

sterilization methods.

- Essential

Principles Checklist – Demonstrating conformity with safety and

performance principles.

- Risk

Analysis – Hazard identification, mitigation measures, and residual risk

evaluation.

- Clinical

Evaluation – Summary of clinical evidence, literature references, or trial

data.

- Labelling

and Packaging – Labels, IFUs (Instructions for Use), symbols, and

compliance with Indian labelling norms.

- Quality

Management System Documentation – Evidence of ISO 13485 certification.

Special Considerations for Dental Devices

Dental devices can vary widely in design, application, and risk

profile. Examples include:

- Dental

implants – Require mechanical testing, corrosion resistance, and

biocompatibility studies.

- Orthodontic

appliances – Materials testing to ensure safety during long-term oral

exposure.

- Dental

filling materials – Need chemical composition analysis and cytotoxicity

testing.

- Dental

X-ray devices – Require radiation safety certification and performance

validation.

Common Mistakes and How to Avoid Them

- Missing

technical documents – Ensure all mandatory annexures are included.

- Using

non-Indian DMF formats – Align with MDR, 2017 templates.

- Insufficient

clinical evidence – Provide literature data or clinical trials relevant to

Indian patients.

- Not

addressing labelling rules – Missing mandatory symbols, language

requirements, or manufacturer details.

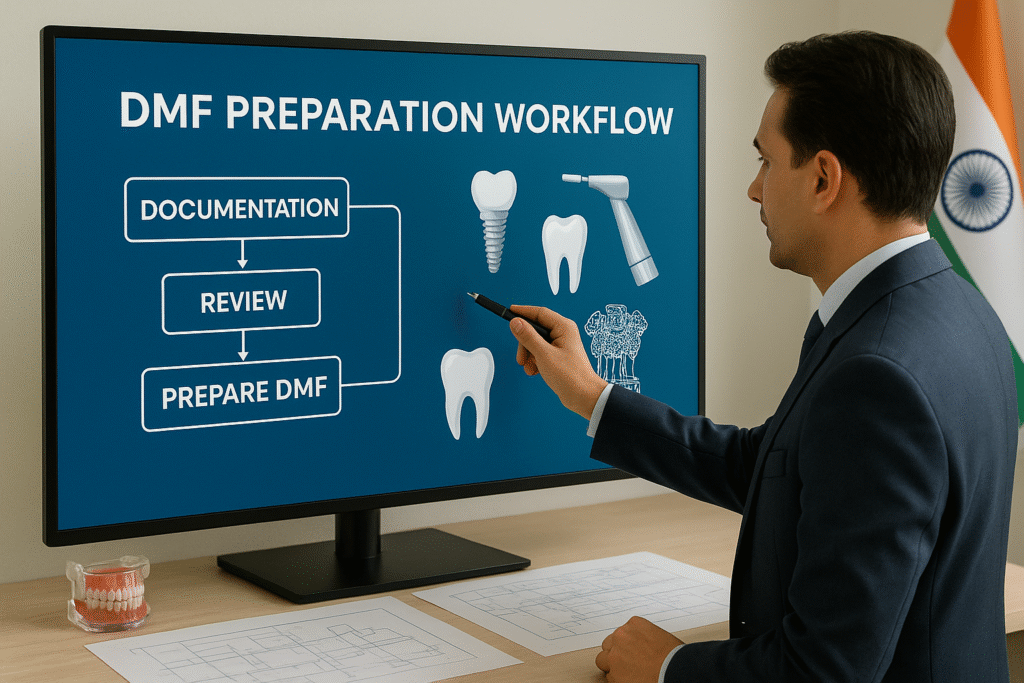

Step-by-Step DMF Preparation Process

1. Planning & Document Collection

- Gather

QMS records, product specifications, risk analysis reports, and testing

certificates.

2. Formatting as per CDSCO Expectations

- Follow

MDR, 2017 annexure format.

- Ensure

all documents are in English (or officially translated).

3. Review & Submission via SUGAM Portal

- Upload

documents in the required format (PDF, digitally signed).

- Pay applicable fees and track application status.

Conclusion

A well-prepared DMF for dental devices is not just a regulatory

requirement—it is proof of your product’s safety and quality. By following CDSCO

guidelines, using MDR, 2017-compliant templates, and keeping the DMF updated,

manufacturers and importers can avoid delays, ensure smooth approval, and

maintain market access in India.

Sources :

- CDSCO

– Medical Device Rules, 2017

- MoHFW

– Medical Devices Overview